The Buzz on Motorcycle Parts New Zealand Specialists

Table of ContentsExcitement About Motorcycle Parts New Zealand SpecialistsThe Basic Principles Of Motorcycle Parts New Zealand Specialists The Greatest Guide To Motorcycle Parts New Zealand Specialists4 Easy Facts About Motorcycle Parts New Zealand Specialists ShownGet This Report on Motorcycle Parts New Zealand SpecialistsThe Greatest Guide To Motorcycle Parts New Zealand SpecialistsMotorcycle Parts New Zealand Specialists Fundamentals ExplainedMotorcycle Parts New Zealand Specialists - The Facts

Get to out to one of our experts today.CNC machining innovation is quickly coming to be the focal point of several production procedures around the globe as a straight result of its lots of benefits over various other methods. In addition, the industries that make motorcycles have actually gotten on board with this trend. The most cutting-edge business are currently establishing their engine components and wheels using machining techniques initially developed for motorcycle components.

You may be wondering why we utilize. Currently that we have your focus allow us explain the rationale behind this contemporary growth in the motorcycle manufacturing market.

The Motorcycle Parts New Zealand Specialists Statements

Additionally, you have complete control over the appearance of the components, also down to the min details. Occasionally, motorcyclists might determine to improve their trip by installing aftermarket parts or modifying the bike's remodeling. When again, computer system numerical control (CNC) machining is one of the most functional method. Upgrades might be of any kind and style you desire.

About Motorcycle Parts New Zealand Specialists

CNC machining might be utilized to make virtually all of a bike's steel and plastic parts. To proceed, we'll go over several machined components for motorcycles.

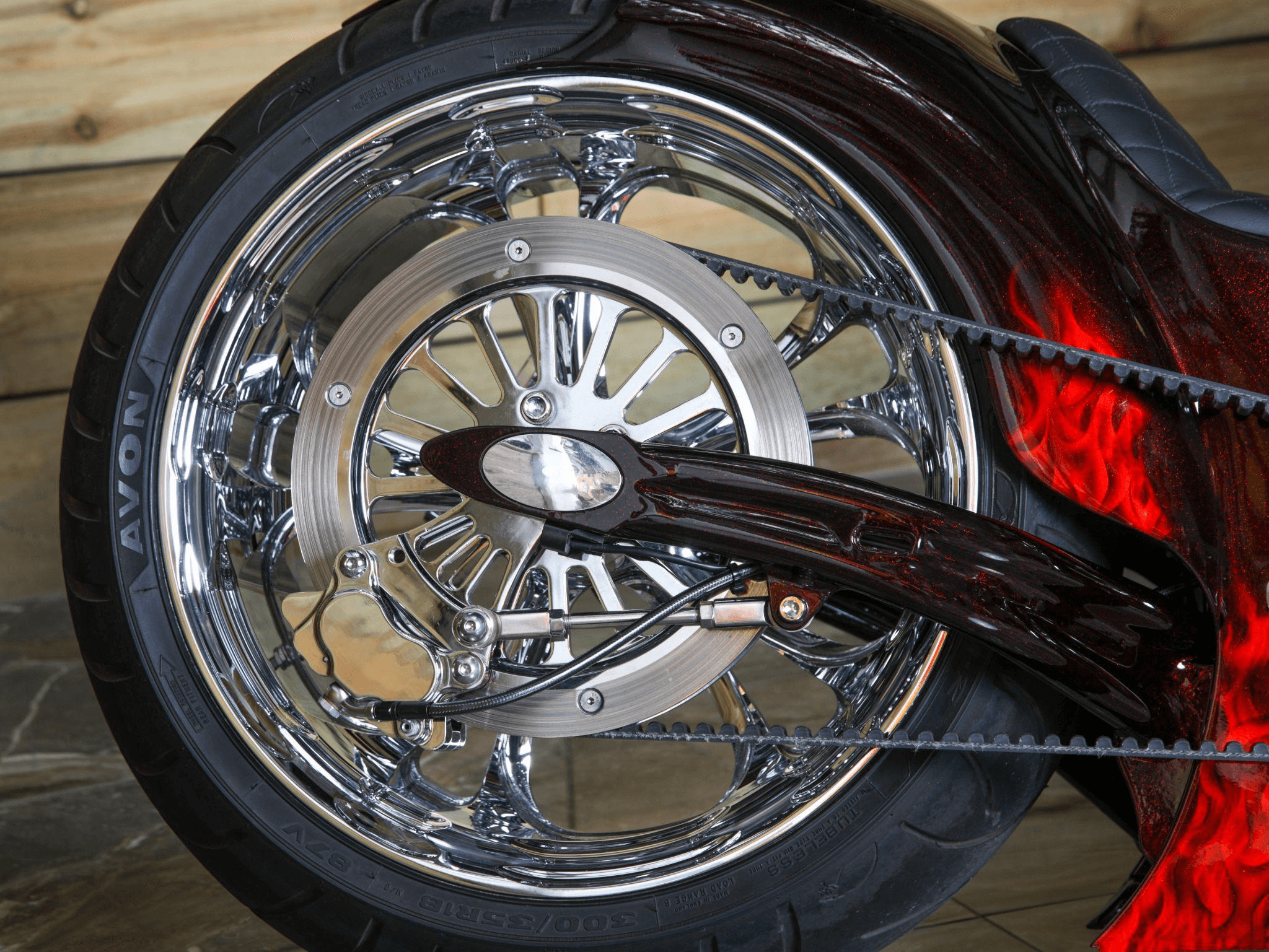

When tailoring the wheels, the disks are where the emphasis needs to be. Most of them are made out of aluminum. Aluminum alloys are well-known for the exceptional machining abilities that they possess. Milling procedures are used to obtain the desired degree of wheel modification. An additional element of the motorbike that may be personalized is the tires.

All About Motorcycle Parts New Zealand Specialists

When it concerns a vehicle (or a motorcycle), the most crucial component is the engine. A number of people mention it as the "heart" of the car. On the various other hand, the camshaft, the cylinder head, and the pistons often tend to be elaborate and call for designs with a high level of precision.

Usage just top quality products, nonetheless, given that these lights are essential for the security of motorcyclists and various other vehicle drivers or people on the road, particularly at evening. Bike fronts lights have 3 major parts: the bulb, or light source, the lens, and the housing.

Milling processes with a perfect surface would lead to the lenses having a reflective top quality that resembles that of a mirror. The cover, on the various other hand, is not made up of Learn More delicate products; instead, it is built out of difficult polymers that can be machined into more elaborate patterns.

Motorcycle Parts New Zealand Specialists for Beginners

They frequently have intricate geometries with a wide range of minute details. Motorcycle suppliers commonly cast these elements, yet only for the production of bespoke components. CNC machining is the method of selection when generating unique pieces. Machining on five axes in today's world is the means whereby any type of style form might be understood.

Pick Runsom for your personalized bike parts! We have the ability to fabricate challenging and stylish parts making your motorcycle unparalleled.

Here are a few instances of metals often utilized in bike component machining. Aluminum is the main product used by business concentrating on producing customized motorbike parts to develop most of these parts. In the past, we would develop our engines out of actors iron. On the various other hand, aluminum is rapidly coming to be the product of choice, partly because of the truth that it is more lightweight.

Zinc refers to another metal that is very light in weight and has excellent machining top qualities because of its high mechanical strength. This material may be formed right into virtually any kind of form and preserves its measurements well. Also mission-critical elements that need a high degree of precision may benefit from their use.

Facts About Motorcycle Parts New Zealand Specialists Revealed

Another steel that sees heavy use in the manufacturing of find more CNC-customized elements is magnesium. It is amongst the lightest steels that are now obtainable and has excellent machinability functions and toughness commensurate with its low weight. Among the drawbacks of magnesium is that its dust might easily ignite.

Due to its superior machinability and weldability, stainless-steel is an alloy that is specifically well-suited for CNC processes. They have fantastic deterioration resistance and a high visual allure. Their most common usage in generating various motorbike discover this info here elements is bolts, such as screws and bolts. Their low vulnerability to oxidation and deterioration makes them optimal for this usage.

The smart Trick of Motorcycle Parts New Zealand Specialists That Nobody is Talking About

It seems that CNC turning and milling are the foundational procedures. In addition, it needs keeping bars of product, most often plastic or metal, in placement and then twisting a reducing tool to remove sections of the product as the material is turned.

These methods are just as vital and generate parts with high precision and constant top quality. The processes aid enhance the general high quality of the machined motorbike parts.

Little Known Facts About Motorcycle Parts New Zealand Specialists.